In this article, we will cover common aspects of process mapping. In addition, we will introduce the Cleverom, a tool for easy and smooth process mapping.

Process mapping is a key component of business development and efficiency improvement. Mapping allows organizations to gain a clear understanding of their operational practices, helping to identify bottlenecks, optimize resource usage, and enhance overall performance.

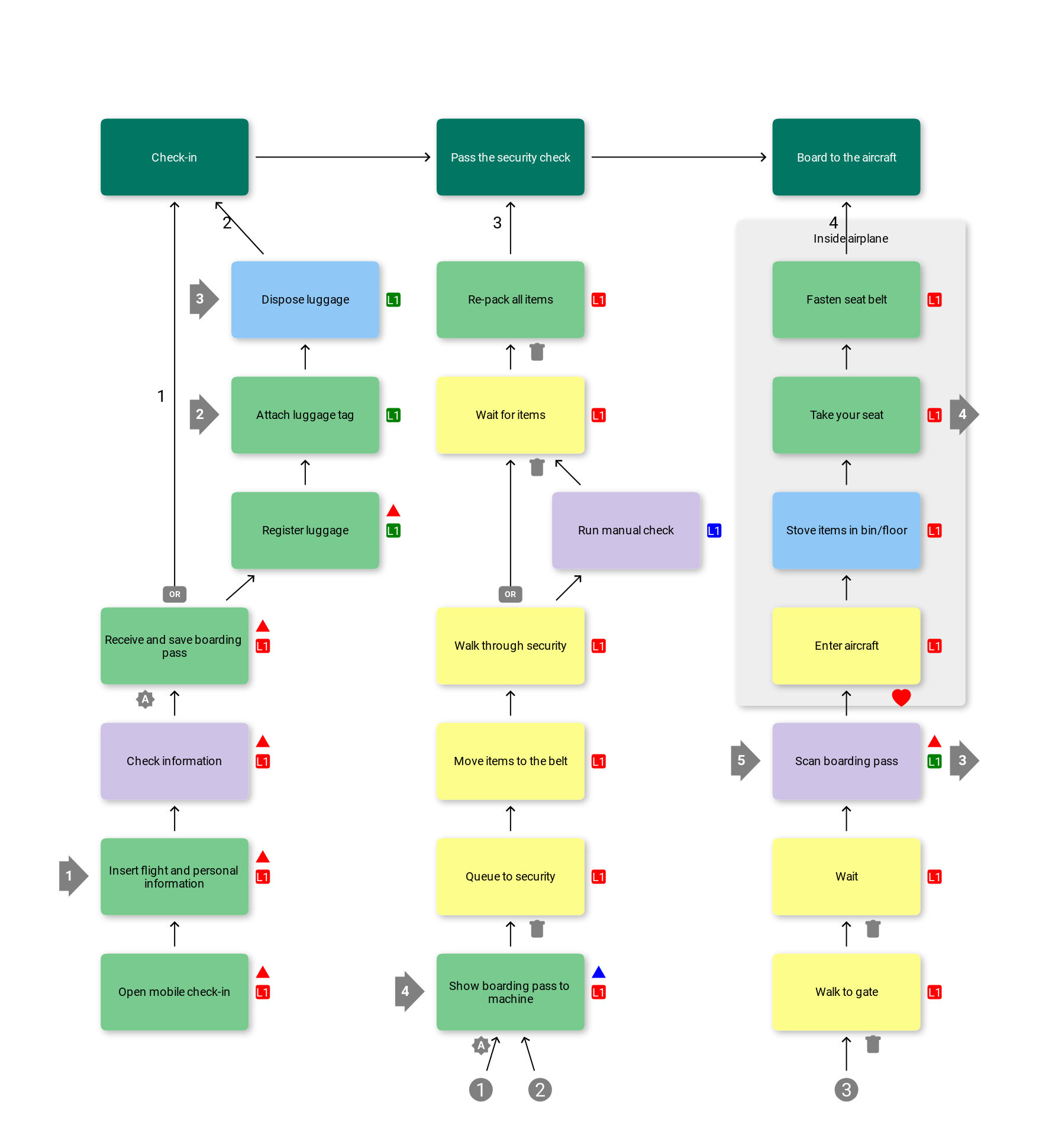

Below is an example of the check-in process at an airport, made using the Cleverom tool. The process map is read from the bottom up and from left to right.

Why is process mapping important?

Process mapping is a crucial part of business development and efficiency improvement. It clarifies resource allocation and highlights opportunities for standardizing operations and eliminating waste. The clear mapping of business processes also helps new employees become acquainted with the organization’s operations more quickly and to align better with its goals.

Process mapping also helps reduce errors and improve internal communication. It serves as the foundation for a culture of continuous improvement, enabling the organization to identify potential issues and make necessary changes effectively.

The role of technology in process mapping

The role of technology is irreplaceable in process mapping. Various diagramming tools, software, and automation techniques make mapping processes easier and more efficient. With the help of visual aids, organizations can create clear and easily understandable process diagrams, while automation can assist in monitoring performance in real time.

Additionally, technology facilitates the updating of processes and ensures that all stakeholders in your organization remain informed. Mapping also enables real-time collaboration between different teams, promoting transparency and effective information exchange.

The long-term benefits of process mapping

The benefits of process mapping extend beyond immediate improvements. Over the long term, organizations can gain enhanced flexibility, a quicker ability to adapt to changes, and continuous learning. Mapping processes lays the groundwork for ongoing improvement and innovation as the organization learns from its own practices and discovers new ways to enhance its operations.

Additionally, process mapping helps organizations remain competitive by enabling them to respond quickly to market changes and customer needs. This long-term perspective makes process mapping a valuable investment in the organization’s success.

Four steps to successful process mapping

A systematic approach is needed for successful process mapping. The four key steps are:

- Defining the process: First, determine which process you want to map. This should include the process’s objectives, expected outcomes, participants, and resources.

- Identifying process steps: Next, identify the steps involved in the process. This can be achieved by interviewing process participants, reviewing process documentation, or observing the process in action.

- Creating the process description: Based on the collected information, create a description of the process. This can be in the form of a visual process map or a written description.

- Evaluating the process description: The process description must be clear and understandable to all intended users. Therefore, it is important to evaluate the process description before implementing it.

Mapping processes using the SHINGO-SIPOC method – what are they?

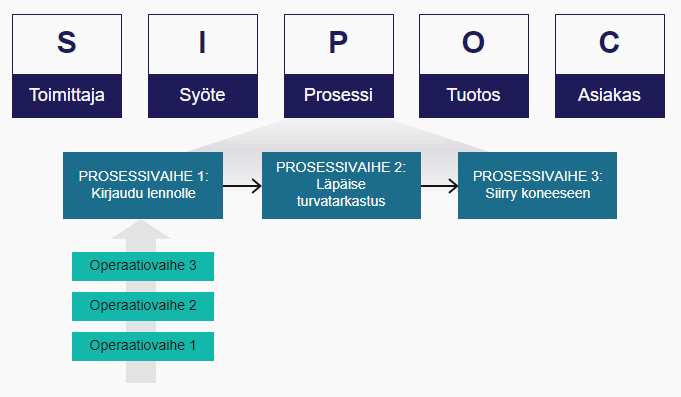

SIPOC method

SIPOC is a process improvement tool that distills the framework of an operation into five key elements: Suppliers, Inputs, Process, Outputs, and Customers. The diagram clarifies the overall process and helps identify stakeholders. Suppliers provide Inputs, which the Process converts into Outputs for Customers. SIPOC provides an understanding of the process, aids in identifying stakeholders, and facilitates clear communication. It helps in spotting improvement opportunities and serves as a foundation for further mapping. SIPOC enhances process management and aids in finding opportunities for improvement to achieve organizational goals.

SHINGO SIPOC together

The SHINGO method and the SIPOC model are two distinct but complementary tools for process description and understanding. The SIPOC model is used to outline the fundamental structure of a process, describing its stages, inputs, suppliers, outputs, and customers. SIPOC helps visualize the overall framework and identify stakeholders. In contrast, the SHINGO method is employed to deepen the understanding of the process and uncover opportunities for improvement.

With the SHINGO method, each SIPOC element is analyzed in detail. The method aims to deliver added value and ensure quality. SHINGO emphasizes continuous improvement, utilizing tools such as the PDCA cycle. Lean principles, like waste elimination and resource optimization, align closely with the teachings of the SHINGO method. Finally, SIPOC and SHINGO are integrated to provide a comprehensive view of the process and its potential areas for improvement.

Cleverom, created by us, is the only tools in the world that allows you to map processes using the SHINGO-SIPOC method.

How to start mapping processes easily and quickly

- 1. Create a free Cleverom account on cleverom.com

- 2. Choose “Shingo” from the tools listed on the right at the bottom

- 3. Select “Create new” and give your Shingo map a name

- 4. Choose the visibility setting as public or private

- 5. After this, you can watch the instructional videos below to learn how to map processes!

How to map processes using Cleverom

Process mapping: the basics of Shingo.

Process mapping: using color coding, organizations and systems.

Process mapping: focusing on Shingo’s value creation, waste and inputs

Process mapping: focusing on Shingo elements, comments and requirements