Process mining promises a lot, but will it deliver?

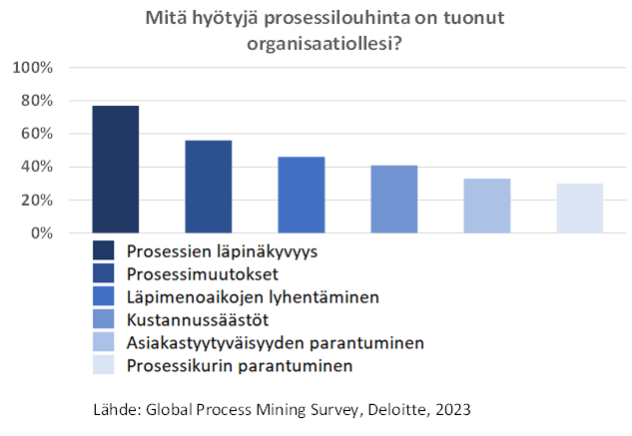

The “Global Process Mining Survey” (2023) conducted by Deloitte, listed six benefits that respondent companies have already realized from process mining. These identified benefits are easy to agree with and could also result from process improvement projects implemented through other methods.

How to get started with process mining?

If you genuinely want to develop and manage processes in a data-driven way, you also need a process improvement process and daily management practices to support it. DMAIC, PDCA and newer innovations like ProcessOps offer tools for developing and implementing findings and improvement suggestions. It is important to plan the path to value creation before scaling experiments into continuous operations.

Benefits of the current state model

Regardless of whether the goal is occasional process mining for problem identification and process analysis, or a daily management tool aimed at continuous monitoring, it is beneficial to begin with a well-prepared current state description (as-is) created by experts.

Why is this important? Isn’t process mining specifically used to find the true current state, identify process variants, and monitor whether the process is being followed or not?

Yes, but the result of process mining is a model. In modeling, it is important to understand the processes and their operation before incorporating data. In practice, this means sensibly defining the process boundaries and modeling work that occurs outside of the systems as a part of the process.

Modeling done using post-it notes or process modeling tools (Cleverom) is not unnecessary or a waste of time. Choosing the right level of detail and grouping process steps into logical segments improves the ability to assess the quality of the mined model.

A typical challenge related to process mining is evaluating the accuracy of the results. Where is the problem? 1) In the data or 2) In how we interpret and act on the data?

Data might not be collected from every process step. Identifying relevant data can be difficult without a detailed current state description created by experts. This challenge is especially significant when mining broader cross-functional processes.

A current state model developed with experts brings clear benefits to process mining

- Level of modeling – An expert understands the context in which the work is done

- Industry understanding – Considering the unique characteristics of the company’s operations

- Business objectives – What are the goals of the process and what aspects are being optimized?

- Speed – Experts develop models quickly and cost-effectively

- Integration of results – Combining the insights from process mining with expert knowledge

In summary, process mining offers organizations significant opportunities for process improvement and optimization. However, its effective utilization requires careful planning, expert involvement, and continuous evaluation of goals and results. This way, organizations can ensure that the promises of process mining are not only fulfilled, but also lead to real value creation and business improvements.

Would you like to learn more about the practical applications of process mining and other process improvement methods?

Book a 30-minute process consultation. After the session, you will have many new ideas and perspectives for improving your operations.